Hello! Today, we're diving into a topic that's a bit technical but incredibly important for our safety: the "Latent Fault" in automobiles. You might think, "My car runs perfectly fine," but the truth is, not all faults make themselves known right away. I'll admit, this concept felt complex to me at first, but once you understand it, you see why it's so critical. Let's explore it together! 😊

What Exactly is a Latent Fault? 🤔

The automotive functional safety standard, ISO 26262, defines a **latent fault** as a fault that is hidden and not detected immediately. By itself, this fault might not cause any immediate trouble. However, it can lie dormant and, when combined with another, completely independent fault, it can lead to a catastrophic safety failure. It's truly a "hidden threat."

For instance, imagine one of a vehicle's redundant sensors fails, but the system doesn't notice. The other sensor is working fine, so the driver is unaware of any issue. But what happens if that second sensor also fails? The vehicle could lose a critical function like steering or braking. This is the danger of the "fault + latent fault" scenario.

- Fault: The root cause, an abnormal condition that could lead to a system failure (e.g., a defect in a semiconductor).

- Error: The intermediate stage where the fault causes an incorrect value or system state.

- Failure: The final result, where the error becomes externally visible and the system no longer performs its required function.

Key Safety Metrics in ISO 26262 📊

The ISO 26262 standard uses several key metrics to evaluate a vehicle's level of safety. There are three primary metrics for assessing its ability to handle random hardware faults.

| Metric | Description | ASIL D Target |

|---|---|---|

| SPFM (Single-Point Fault Metric) | Shows how well the system prevents a single fault from directly causing a hazard. | ≥ 99% |

| LFM (Latent Fault Metric) | Shows how well hidden, multi-point faults are detected and handled. | ≥ 90% |

| PMHF (Probabilistic Metric for Hardware Failure) | Represents the average probability of a dangerous failure per hour. | < 10 FIT (10⁻⁸ per hour) |

In simple terms, SPFM and LFM are quality indexes that show how robust the design is, while PMHF is an absolute probability that shows how rarely a dangerous failure will actually occur. A higher LFM means the system has stronger defenses against latent faults.

This isn't just theory; latent faults have been the root cause of major recalls. The 2020 Chevrolet Bolt EV battery fires were caused by two latent manufacturing defects (a torn anode tab and a folded separator) existing in the same battery cell. The infamous Takata airbag recall was also due to a latent defect: the chemical propellant degrading slowly over years.

Catching the Culprit: Safety Mechanisms 🛡️

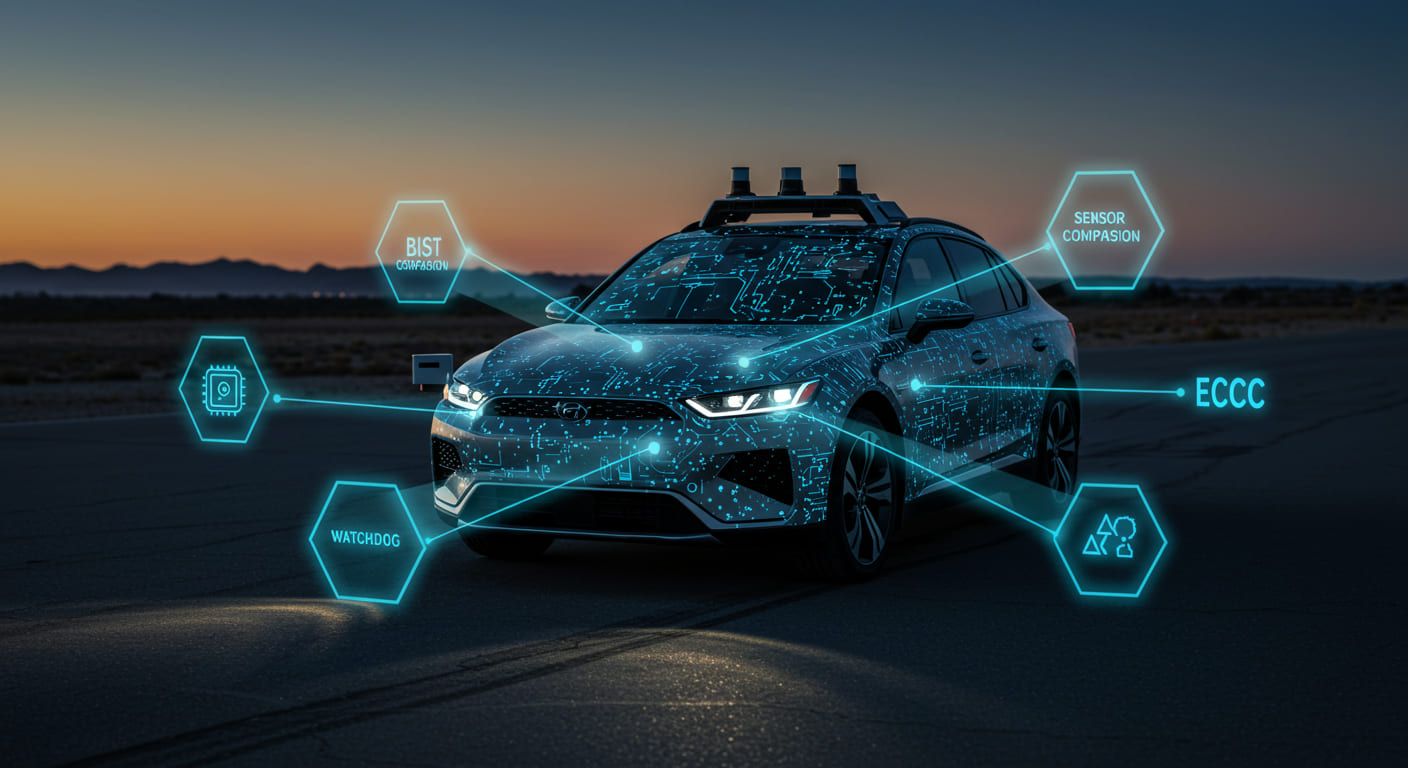

So, how do car manufacturers find and prevent these sneaky faults? They rely on "safety mechanisms." Modern cars are packed with countless safety systems working silently behind the scenes.

📝 Examples of Key Safety Mechanisms

- Built-In Self-Test (BIST): The system checks its own hardware health at startup or periodically during operation.

- Sensor Comparison: Outputs from redundant sensors are compared to detect any inconsistencies.

- Watchdog Timers: Monitors if the CPU is running correctly and reboots it if it freezes.

- Error Correction Code (ECC): Detects and automatically corrects bit errors in memory data.

For Level 3 and higher autonomous vehicles, these mechanisms are even more critical. Since the driver isn't always monitoring the road, the system must be able to detect latent faults and transition to a safe state on its own, a concept known as "Fail-Operational" architecture.

Latent Faults at a Glance

Frequently Asked Questions ❓

Today we've looked at the critical concept of 'latent faults' in automotive functional safety. It might have been a bit deep, but I hope it provides insight into how sophisticated and complex the safety mechanisms in our cars truly are. If you have any more questions, feel free to leave a comment! 😊

'ISO26262' 카테고리의 다른 글

| [ISO 26262] #2. Complete Guide: Common Cause vs. Cascading Failures, No More Confusion! (3) | 2025.06.22 |

|---|